Question:

In my current deepwater project, we're drilling with a subsea wellhead using a dynamically positioned rig. How do I determine safe operating limits for rig movement, and what technical and procedural steps should I follow to ensure riser integrity and prevent well control issues if the vessel starts to drift?

DrillDesk Response:

In deepwater drilling, using a subsea wellhead, floating rigs such as drillships or semi-submersibles are connected to the wellhead on the seabed through a marine riser. While the riser forms a critical link between the rig and the well, floating rigs naturally move due to wind, waves, and currents. These movements are controlled using mooring systems or Dynamic Positioning (DP) thrusters.

However, even with these systems, some movement is inevitable. When the rig moves, it creates an angular load on the riser at the seabed connection point. Riser systems are designed to tolerate only a small range of angular deflection—typically between 2 and 4 degrees. Exceeding this limit can result in serious issues, such as riser buckling, fatigue, or even catastrophic failure, potentially leading to a loss of well control.

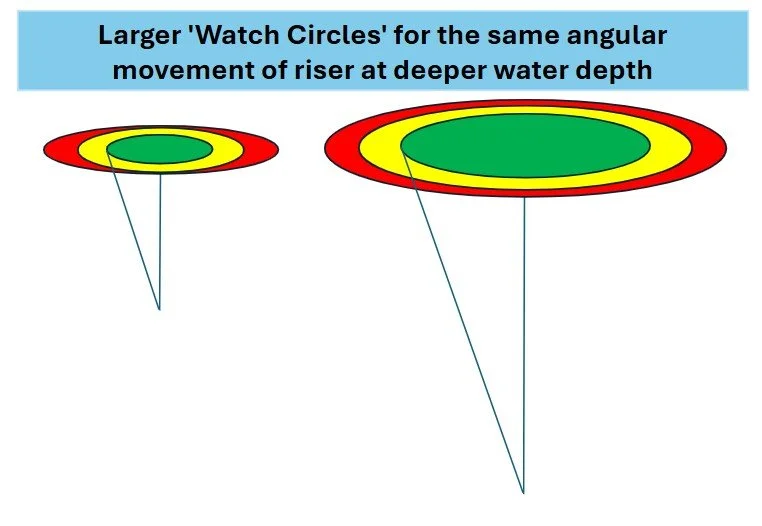

To manage this, a watch circle is defined. This is the allowable surface area within which the rig can safely move while remaining connected to the subsea wellhead. The radius of the watch circle is directly related to the water depth and the riser's allowable angle. For example, a 2-degree riser deflection limit translates to a radius of approximately 3.5 meters at a water depth of 100 meters and about 35 meters at a water depth of 1,000 meters.

In shallow waters, this radius becomes much smaller, making operations more sensitive to environmental forces such as tides and coastal currents. Although floaters can technically operate in shallow water if their draft permits, the restricted watch circle and dynamic environment make such operations riskier.

To ensure safety, watch circles are commonly divided into color-coded zones—green, yellow, and red—each representing different levels of operational risk and requiring specific actions:

Green Zone:

Vessel is within the safe operating range.

Normal drilling activities continue.

Position is tracked using GPS, acoustic beacons, and riser angle sensors.

Yellow Zone:

Vessel is nearing the safe movement limit.

Increase monitoring of rig position, weather, and riser status.

Adjust moorings or increase DP thrust as needed.

Suspend non-critical operations like tripping pipe.

Notify key personnel and prepare for possible escalation.

Red Zone:

Vessel is at or beyond safe limits.

Immediately halt drilling to minimize stress on riser and wellhead.

Begin emergency procedures, such as preparing for LMRP disconnect.

For DP rigs, maximize thrust or initiate a drift-off.

For moored rigs, adjust or, if necessary, release anchors.

If weather conditions worsen, prepare for full emergency disconnect and relocate the rig.

A proper understanding and response to watch circle limits are vital for protecting riser integrity and maintaining well control in floating drilling operations. A conceptual diagram (not to scale) is shown below: