Compact Wellheads in Oil and Gas Drilling

1. What Is a Compact Wellhead?

A compact wellhead is a unitized surface wellhead assembly engineered to support and seal multiple casing and tubing strings within a single integrated housing rather than using stacked spool components. This housing provides structural support and a pressure-control interface between subsurface tubulars and surface pressure equipment for both drilling and production operations. Compact wellheads perform the same essential functions as conventional wellheads, namely casing suspension, pressure sealing, and connection of blowout preventers (BOP) and Christmas trees, but are designed to do so with a reduced physical footprint and fewer external connections.

2. Principal Differences Between Compact and Conventional Wellheads

Structural Form:

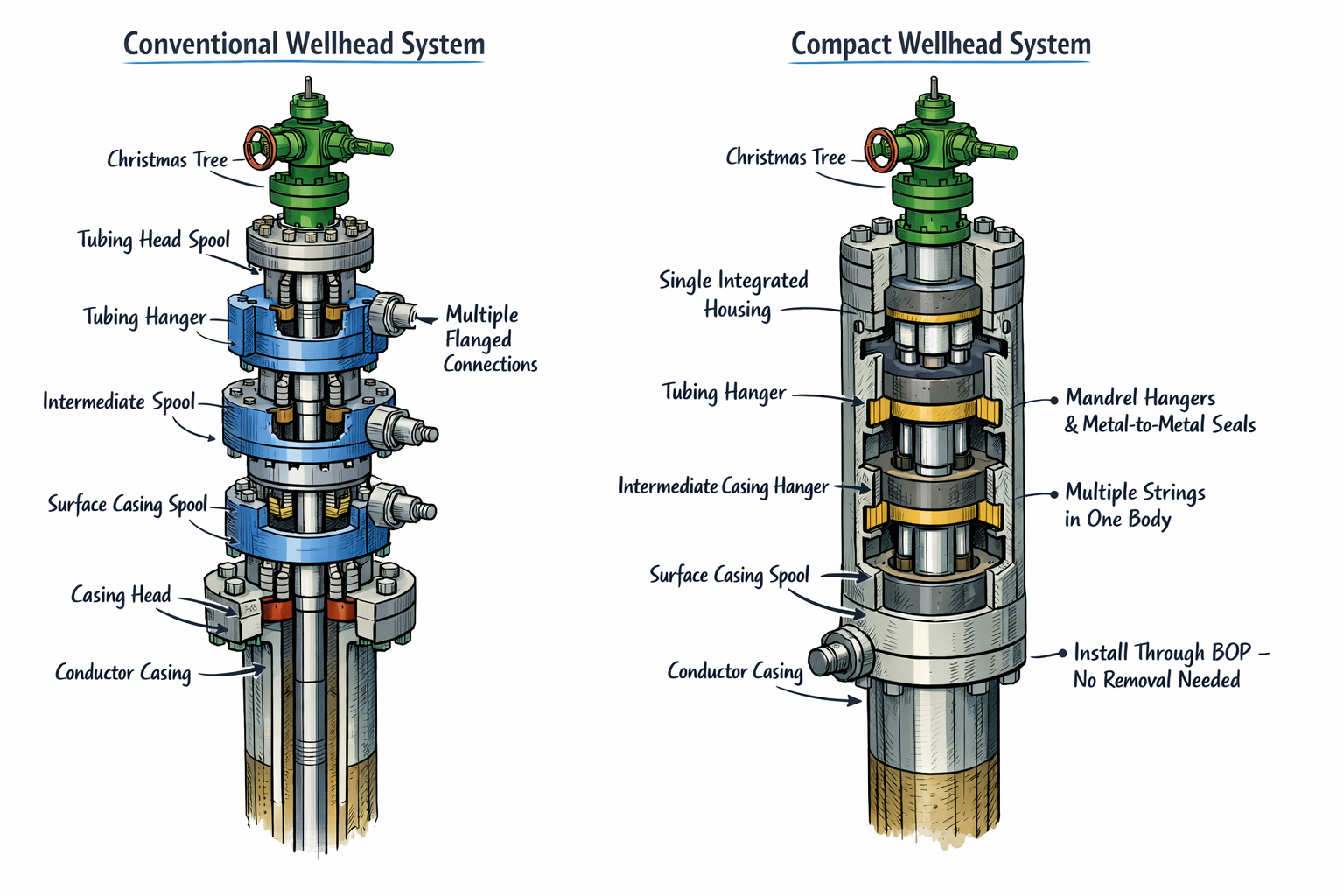

A conventional wellhead is built from multiple individual components (casing heads, spools, tubing heads), each stacked and bolted together. A compact wellhead instead uses a single unitized housing that contains internal shoulders and seals to suspend all required casing strings and tubing.Installation Process:

In a conventional setup, each casing string requires removing the BOP stack, installing a new spool, setting the hanger and seals, and then reinstalling the BOP. In contrast, compact systems are designed to allow multiple casing strings to be landed and sealed through the BOP stack without removing it.Physical Footprint:

Because compact wellheads combine many functions into a single housing, they occupy much less vertical and horizontal space. This is especially helpful on offshore platforms, in restricted pad drilling sites, or when cellar space is small.Flange & Connection Count:

Conventional systems have many flanged joints and seal interfaces, each of which represents a potential leak path and an HSE exposure point. Compact wellheads minimize these interfaces.A conceptual drawing comparing a ‘Conventional Wellhead System’ and the ‘Compact Wellhead System’ is shown below.

3. Advantages of Compact Wellheads

Reduced Installation Time:

Compact wellheads dramatically reduce the time required to install surface pressure control equipment by eliminating repeated BOP breakdowns and spool make-ups. This can reduce rig time by up to 40–45% compared to traditional multispool installations.Smaller Footprint:

Because compact wellheads consolidate multiple components into a single body, the overall height and footprint of surface equipment are significantly reduced, a major advantage in locations with limited space, such as offshore platforms or tightly spaced pad drilling sites.Enhanced Safety:

Fewer components mean fewer connections that operators and rig crews need to handle. Each flange or mechanical joint is a potential source of leakage or HSE exposure, so fewer of them reduces both leak risk and manual handling hazards. Moreover, the fewer BOP make/break cycles required with compact systems reduce personnel exposure to high-energy equipment movements.Improved Seal Reliability:

Modern compact wellheads often incorporate advanced sealing mechanisms such as metal-to-metal seals and mandrel hangers that offer long-life, high-integrity pressure sealing even under severe service conditions (e.g., high pressure or temperature).Design Flexibility:

Many compact designs support two-stage and three-stage configurations, meaning they can accommodate two or three additional strings (casing and tubing), thereby fitting a wide range of well programs.

4. Drawbacks and Caution Points

Higher Up-Front Cost:

The precision engineering required for compact housings typically results in a higher initial equipment cost compared to basic conventional wellheads. However, these costs are usually offset by savings in rig time and reduced NPT (non-productive time).Maintenance Access:

Because compact wellheads integrate many functions into a single body, accessing an internal component for service may require removing part or all of the assembly, whereas in a conventional system, you might replace individual spools or packoffs.Planning for Contingencies:

Compact systems require careful planning when there are changes in casing programs, unexpected stuck pipe events, or debris accumulation, because internal access can be more challenging. Some compact designs mitigate this by offering splittable bodies or emergency cut-in capabilities.Tooling Compatibility:

Operators must ensure that all running tools, cementing equipment, and emergency tooling are compatible with the compact design, particularly mandrel hangers and slip connectors, to avoid unexpected rig delays.

5. Installation Sequence Differences

Conventional Wellhead Installation

Set the conductor casing and attach the conductor head.

Run surface casing, remove BOP, install surface casing spool, hang casing, set seals, reinstall BOP.

Repeat step 2 for each subsequent casing string (intermediate, production).

Install the tubing head, then the Christmas tree, after all casing strings are set.

Compact Wellhead Installation

Set the conductor casing and secure the compact wellhead housing.

Run surface casing and set it with a mandrel hanger or slip hanger within the compact housing without removing the BOP stack.

Run intermediate and production casing sequentially, using the same housing’s internal shoulders and seals to suspend and seal each string through the BOP stack.

Run and land the tubing hanger and complete the installation of the Christmas tree or production valves through the same unit.

The key difference is that compact wellheads allow multiple casing and tubing strings to be landed and sealed without repeatedly removing and reinstalling the BOP stack, thereby saving significant rig time and reducing complexity.

6. Manufacturers and Compact Wellhead Variants

Several companies specialize in compact wellheads, offering configurations such as two-stage and three-stage types. The two-stage heads can either hang two strings of casing or one string of casing and one of tubing. The three-stage heads can hang either three strings of casing or two strings of casing and one of tubing. Notable manufacturers include

Baker Hughes - Compact Multibowl systems

SLB (Schlumberger) — Cameron SOLIDrill, Adapt IND, and Single-Trip Systems

TechnipFMC - Unihead systems

Worldwide Oilfield Machine (WOM) — SPII Compact Wellheads

Moto Mecánica Argentina (MMA) — CCP, CCS, CCPI, CCSI Compact Heads

OMS Compact Wellheads (SLS/DLS Systems)

7. Typical Applications and Use Cases

Offshore Platforms:

Compact wellheads are particularly advantageous offshore, where vertical space is limited and rig time costs are high.Onshore Pad Drilling:

On multi-well pads with limited cellar depth, compact designs reduce the cellar excavation requirement and improve rig turnaround.High-Pressure/High-Temperature Wells:

Advanced compact systems rated for severe service conditions can safely operate under challenging pressure and temperature profiles.Unconventional Shale and Batch Operations:

The speed and modularity of compact wellheads support high-volume drilling campaigns requiring rapid installation and offline operations.Contingency-Sensitive Sites:

Compact heads with features such as mandrel hangers that repel debris and internal lockdown mechanisms enhance reliability at remote or constrained sites.

8. Cost and Safety Considerations

Rig Time Savings Equals Cost Reduction:

Because compact wellheads reduce BOP make/break cycles and streamline casing-to-surface operations, they directly reduce rig time, often the single largest cost driver in drilling operations.HSE Risk Reduction:

With fewer flanges and fewer personnel interactions with high-energy equipment, compact systems lower routine operational risk. They also reduce the exposure necessary for wellhead make-ups and breakdowns.Inventory and Logistics Efficiency:

Compact designs use standardized component interchangeability across casing programs, simplifying logistics and reducing inventory carrying costs for operators.

References

Baker Hughes. (2026). Compact Multibowl Wellhead Solutions. Baker Hughes Website. https://www.bakerhughes.com/surface-pressure-control/compact-multibowl-wellhead-solutions

Drilling For Gas. (2026). Selection Guidelines for Wellhead Equipment. Drilling For Gas Website. https://drillingforgas.com/completion/equipment-completion/selection-guidelines-for-wellhead-equipment/

Speight, J.G. (2026). Wellhead - an Overview. ScienceDirect Topics. https://www.sciencedirect.com/topics/engineering/wellhead

Goldenman. (2025). Which Wellhead Equipment Is Right for Your Oil and Gas Project. Goldenman Website. https://goldenman.com/wellhead-equipment-comparison-for-oil-and-gas-projects/

TechnipFMC. (2026). Wellhead Technology Brochure. TechnipFMC PDF. https://www.technipfmc.com/media/tanlm3fg/wellhead-technology-brochure_digital.pdf

SLB. (2024). Compact Wellhead Benefits Equinor. SLB Case Study. https://www.slb.com/resource-library/case-study-with-navigation/sur/cameron-fontus-wellhead-cs

Simple Engineering Articles. (2019). Compact Wellhead. WordPress Blog. https://simpleengineeringarticles.wordpress.com/2019/08/12/compact-wellhead/

SLB. (2016). Compact Wellheads Minimize Environmental Impact. SLB Case Study. https://www.slb.com/resource-library/case-study-with-navigation/sur/compact-wellheads-kenya-cs

SPE. (1989). Development, Application, and Utility of Compact Wellhead Systems. SPE Paper 19524-MS. https://onepetro.org/SPEATCE/proceedings-abstract/89SPE/89SPE/63719

OMSOS. (2023). SLS and DLS Compact Wellhead Systems. OMSOS PDF. https://www.omsos.com/wp-content/uploads/2023/11/OMS-Unitized-Wellhead-Brochure-Jan2022.pdf

Al-Humeedi, A. (2023). What are Compact Wellheads. LinkedIn Post. https://www.linkedin.com/posts/ali-al-humeedi-9151a922b_what-are-compact-wellheads-compact-wellheads-activity-7066624996265074688-53It

GlobalSpec. (2024). Revolutionizing Wellhead Installations. GlobalSpec Article. https://insights.globalspec.com/article/21925/revolutionizing-wellhead-installations-with-the-cameron-adapt-nst-for-unconventional-shale-plays

Stream-Flo. (2025). Wellhead 101. Stream-Flo Website. https://streamflo.com/wellhead-101-what-is-a-wellhead-and-how-does-it-work/

SLB. (2022). Cameron Wellhead Systems. SLB Website. https://www.slb.com/products-and-services/innovating-in-oil-and-gas/well-construction/wellhead-systems

Disclaimer: This guide synthesizes and paraphrases industry best practices from referenced sources for educational and field-reference purposes only. It does not reproduce copyrighted material verbatim and is not official company policy or engineering advice. All information belongs to the original authors and publishers who retain full rights. No claim of original authorship is made for referenced concepts, and the document is distributed in good faith for drilling professionals.