Case Study: Applying the IADC Geothermal Well Classification

A project team was tasked with designing and planning a new geothermal well. To create a clear picture of the challenges, they applied the IADC Geothermal Well Classification System.

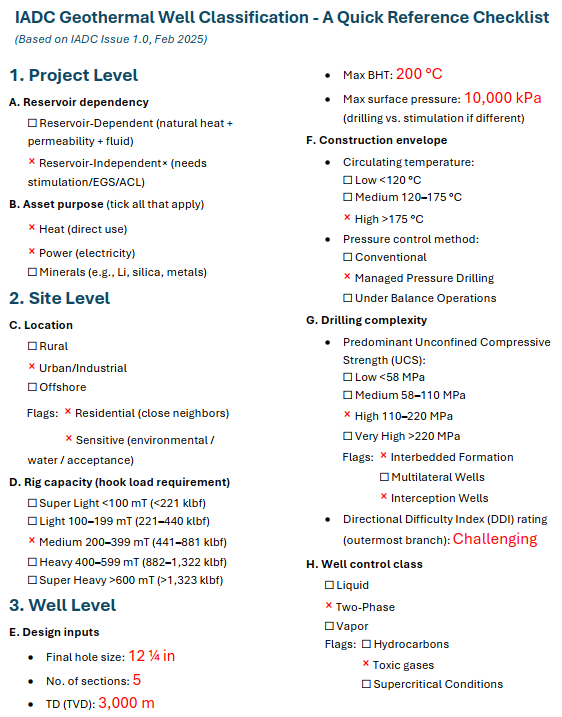

Project: Reservoir-Independent; Power + Heat

Site: Urban; Flags—Residential & Sensitive

Rig capacity: Medium (≈300 mT hook load)

Design: Final 12¼" production hole; 5 sections; TVD 3,000 m; Tmax 200 °C; Pmax 10,000 kPa (stimulation Pmax higher than drilling)

Construction: High circulating temperature; MPD planned for fracture gradient window

Drilling complexity: High UCS (basalt/granite), Interbedded; DDI “Challenging”; one planned interception

Well control: Two-Phase; Flags—Toxic gases (CO₂, H₂S)

The team decided to use the Checklist as a quick reference.

Project Level

The resource was classified as Reservoir-Independent. Heat was available in the subsurface, but the natural permeability was too low for commercial production. This meant stimulation or engineered Enhanced Geothermal Systems (EGS) would be required.

The well’s purpose was dual: to supply power generation and also provide direct-use heat. This dual objective influenced the design since the well needed to deliver high flow rates for the power plant while also supplying usable heat to nearby facilities.

→ Impact: The team recognized early that additional cost, stimulation design, and surface facility tie-ins would be necessary.

Site Level

The location was in an urban area, with Residential and Sensitive flags. This meant tighter noise, light, and environmental restrictions, plus more demanding permitting. Community acceptance became a critical factor in planning.

A Medium rig (≈300 mT hook load) was available regionally and matched the well’s depth and casing program. However, the team also noted the need to account for torque and drag due to large hole diameters and long casing strings.

→ Impact: Early rig screening and community engagement were built into the schedule and cost estimate.

Well Level

The well was designed with a 12¼" final production hole, five casing sections, and a true vertical depth of 3,000 m. The expected maximum bottom-hole temperature was 200 °C, and surface pressure could reach 10,000 kPa during drilling (with higher pressures anticipated during stimulation).

Because of the high circulating temperature, the drilling program specified temperature-rated tools, cements, and elastomers. Managed Pressure Drilling (MPD) was planned to safely navigate the narrow fracture gradient window.

The geology consisted of basalt and granite (high UCS), with interbedded layers. Drilling would be slow and abrasive, with frequent BHA wear. The well path was classified as “challenging” on the Directional Difficulty Index (DDI), and one planned interception well was included to enhance stimulation connectivity.

For well control, the reservoir was classified as Two-Phase with flags for toxic gases (CO₂, H₂S). This required special well control procedures, rotating control devices, quenching methods, H₂S contingency planning, and robust surface safety systems.

→ Impact: Engineering teams identified high risks upfront such as bit wear, directional steering challenges, MPD requirements, and toxic gas hazards, allowing for proper tool selection, crew training, and safety systems in advance.

Outcome

By classifying the well systematically, the team avoided blind spots. Instead of treating it as a “typical geothermal well,” they recognized:

It required engineered stimulation, not just drilling into a hot aquifer.

Urban constraints would influence rig choice, permitting, and community relations.

High-temperature and high-strength formations demanded specialized equipment.

Well control hazards (two-phase fluids, H₂S/CO₂) required enhanced safety planning.

This approach itemizes upfront what the rig, BOP, procedures, and team must be ready to handle before the engineer prepares AFE avoiding the risk of overspending due to overlooked requirements for the well.