Managed Pressure Drilling (MPD) – Fundamentals and Field Learning Guide

Table of Contents

Introduction: What is MPD and Why It Matters

Core Concepts & Definitions

Value Proposition, Advantages, Limitations, and Flexibility

Standards, Recommended Practices & Regulatory Guidance

Training, Competence & Human Factors

References, Further Reading, and Image Credits

1. Introduction: What is MPD and Why It Matters

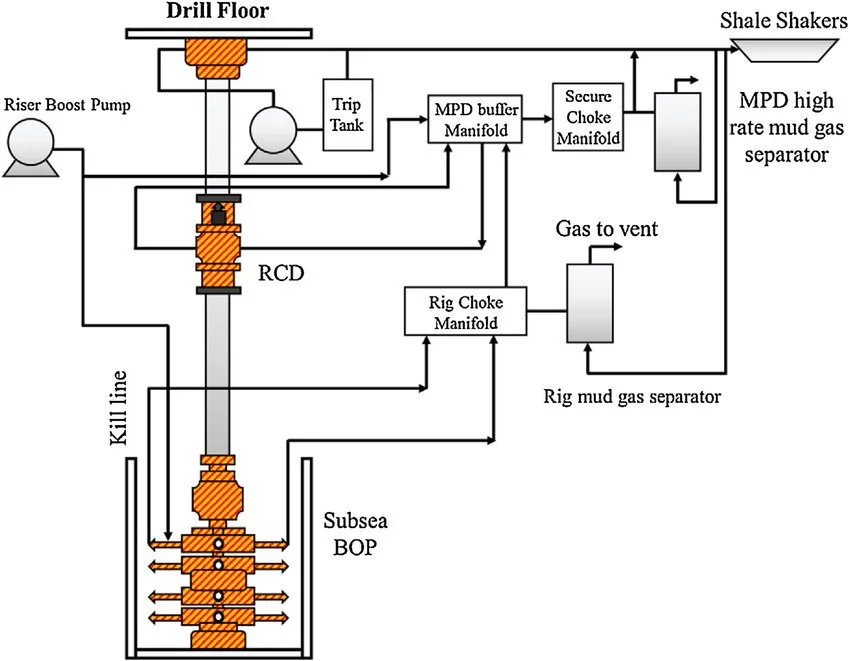

Managed Pressure Drilling (MPD) is an innovative drilling technique that helps manage and control the bottomhole pressure (BHP) within a safe range. Unlike traditional drilling, which primarily relies on static mud weight to balance formation pressures, MPD provides a more flexible approach by enabling real-time control over various pressure-related factors. This ensures the stability of the wellbore, reducing the chances of formation fluid entering the well, significant fluid losses, and other well control problems.

MPD systems can be manual, semi-automated, or fully automated, with capabilities for real-time monitoring, surface backpressure management through automated chokes, and continuous data feedback. By adjusting factors such as circulation rate (which impacts Equivalent Circulating Density, or ECD), surface backpressure, and the levels of fluid in the annulus or riser, MPD keeps BHP within a safe drilling zone. This method enables the quick detection of kicks and losses, allowing for the careful management of minor influxes without interrupting the drilling process.

This technique is especially useful in situations with tight pressure windows or challenging geological formations, where traditional drilling methods may lead to problems such as losses or influxes into the formation. MPD promotes continuous circulation, enhances safety during pipe connections, improves trajectory planning, and increases the reach of drilling intervals. As a result, it helps reduce non-productive time (NPT) and boosts overall drilling efficiency.

2. Core Concepts & Definitions

2.1 Annular Pressure Profile (APP)

The annular pressure profile (APP) describes the distribution of pressure along the annulus of the wellbore. APP is influenced by the hydrostatic pressure of the drilling fluid column, frictional losses due to circulation, and any applied backpressure. By actively controlling these variables, MPD systems maintain a safe and consistent bottomhole pressure, preventing the wellbore from becoming under- or overbalanced.

2.2 Bottom Hole Pressure (BHP)

Bottomhole pressure (BHP) refers to the pressure at the base of the wellbore and is a critical parameter for safe drilling operations. MPD systems often target a Controlled Bottomhole Pressure (CBHP) to ensure that the formation is neither underpressured, which can lead to influxes, nor overpressured, which can cause losses. Maintaining BHP within the safe envelope is the core principle of MPD.

2.3 Equivalent Circulating Density (ECD)

Equivalent Circulating Density (ECD) represents the effective density of the drilling fluid at depth during circulation, accounting for frictional pressure losses. ECD management is critical in MPD operations because even small deviations can cause the bottomhole pressure to move outside the safe window. MPD systems dynamically adjust circulation rates and account for annular geometry to maintain an optimal ECD.

2.4 Drilling Window

The drilling window, also known as the pressure window, is defined as the safe pressure interval between the pore pressure (the minimum BHP to prevent influx) and the fracture pressure (the maximum BHP to prevent losses). MPD expands the effective drilling window by dynamically controlling backpressure, ECD, and other operational parameters.

In large window scenarios, conventional drilling is generally sufficient.

In narrow or high-risk windows, MPD is strongly recommended to maintain safe operations and minimize the risk of kicks or losses.

2.5 Kick/Influx and Losses

A kick or influx occurs when formation fluids enter the wellbore due to a bottomhole pressure that is below the formation pressure. MPD systems enhance operational safety by enabling early detection and a controlled response to such events.

Losses refer to the situation where drilling fluid escapes into the formation due to excessive bottomhole pressure. MPD minimizes losses through continuous monitoring and adjustment of pressure parameters, maintaining a balance that protects the wellbore while ensuring drilling efficiency.

3. Value Proposition, Advantages, Limitations, and Flexibility

3.1 Advantages

Managed Pressure Drilling provides several operational benefits:

Enables drilling in narrow pressure windows

MPD enables the precise control of downhole pressure compared to conventional circulating systems. By actively managing equivalent circulating density (ECD) and surface back-pressure, MPD keeps bottom-hole pressure inside a tight “drilling window” between pore pressure and fracture pressure. This capability enables drilling formations that would otherwise be unsafe using conventional methods.

Earlier and more reliable kick and loss detection

Because MPD systems continuously monitor and control surface pressure and flow with higher resolution, small changes in flow or pressure trends are detected earlier than with many conventional setups. Precise flow balancing and trending make it easier to distinguish normal operational changes (such as pump starts, connections, and mud returns) from early signs of influx or losses. Early detection reduces the need for emergency responses, shortens reaction time to developing kicks, and improves the chance of handling events without escalation.

Greater operational flexibility and reduced NPT

With the ability to adjust surface back-pressure and rapidly respond to dynamic downhole conditions, MPD provides the drilling team with more options to continue drilling through troublesome zones (for example, sections with narrow margins, depletion, or overpressured pockets) rather than tripping out or sidetracking. This flexibility translates directly into less non-productive time (NPT) and lower overall project cost.

Improved Rate of Penetration (ROP)

Managed Pressure Drilling helps increase the rate of penetration by maintaining the bottomhole pressure closer to the ideal balance between pore and fracture pressures. This controlled pressure environment reduces excessive overbalance, allowing the bit to cut rock more efficiently.

Better Hole Cleaning and ECD Control

With MPD, the equivalent circulating density (ECD) can be actively managed to prevent cuttings from settling or packing off. This keeps the annulus cleaner and stabilizes flow, allowing higher bit RPM and WOB without risking stuck pipe or hole cleaning issues. Consistent hole cleaning means higher sustained ROP, especially in high-angle or horizontal wells.Reduced Circulation Interruptions and Fewer Trips

Because MPD manages pressure proactively, drilling can continue through zones that would normally cause losses or kicks with conventional methods. This means fewer unplanned shutdowns, mud conditioning trips, or sidetracks. Continuous, stable drilling leads to a higher average ROP across the well section.

3.2 Limitations and Risks

While MPD provides significant advantages, it also introduces certain complexities and risks:

Complexity and Training: MPD requires specialized equipment, integrated control systems, and personnel trained in both operational and safety procedures. Human errors, if not mitigated, can compromise well integrity.

Equipment and Logistics Costs: Setup, certification, and maintenance of MPD equipment increase project expenditures. A thorough cost–benefit analysis is essential during the planning process.

Potential Failure Modes: Risks include sensor misreads, choke malfunction, RCD seal wear, or inadequate gas handling. These must be addressed through redundancy, monitoring, and adherence to API/IADC recommended practices.

3.3 System Flexibility

Managed Pressure Drilling (MPD) systems are designed to be highly flexible and can adapt to a wide range of drilling and wellbore operations. Their ability to monitor and control annular pressure in real time makes them suitable for maintaining well stability under changing downhole and surface conditions. The key operational modes supported by MPD include:

Drilling: During active drilling, the MPD system continuously adjusts the surface choke to maintain a constant bottomhole pressure (CBHP). These dynamic adjustments ensure that pressure remains within the desired drilling window, even as mud properties, flow rates, or formation conditions change.

Reaming and Back-Reaming: While reaming or back-reaming through tight spots or sensitive formations, MPD monitors and compensates for the swab and surge pressures created by pipe movement. This prevents unwanted influxes when pulling upward or formation breakdown when moving downward.

Pulling Out of Hole (POOH): When pulling out of the hole, annular pressure tends to fluctuate due to changes in displacement and fluid movement. The MPD system closely tracks these variations and automatically applies surface backpressure as needed to maintain a stable bottomhole pressure, thereby preventing both influxes and losses.

Loss of Circulation Detection: MPD flow meters provide continuous, high-resolution measurements of both flow-in and flow-out. Any discrepancy between the two is detected almost instantly, allowing the crew to identify and respond to potential losses or kicks before they escalate.

Tripping Operations: During tripping, the MPD control software anticipates and compensates for the transient pressures generated by pipe movement. This active pressure management ensures that the bottomhole pressure remains within safe limits, minimizing the risk of wellbore instability or fluid influx.

MPD’s flexibility enables it to maintain precise pressure control across multiple operational phases, from drilling and reaming to tripping and circulation management, allowing crews to operate safely and efficiently even in challenging well conditions.

4. Standards, Recommended Practices & Regulatory Guidance

IADC: Provides UBO/MPD Committee recommendations, operator guidelines, and HSE planning documentation.

API RP 92 Series: Covers recommended practices for MPD system design, surface equipment, and CBHP operations. Operators should reference the relevant edition for their application (e.g., 92M for surface systems, 92C for subsea operations).

Classification Societies: ABS and other classification bodies provide guidance and certification for MPD-ready rigs.

Vendor Best Practices: Operators should consult documentation from SLB, NOV, Weatherford, and MPD literature to ensure proper equipment use and maintenance.

5. Training, Competence & Human Factors

Effective MPD operations require well-trained personnel and robust operational procedures.

Training: All personnel, including drillers, MPD operators, HSE staff, and rig management, must undergo structured MPD training covering theoretical principles, HMI/software operation, emergency response procedures, and practical rig-up/rig-down exercises.

Procedures & Communication: Clear role definitions, comprehensive checklists, and scenario-based drills such as HAZOP exercises reduce human error and improve operational reliability.

6. References & Further Reading Technical References

IADC, Guidance for UBO and MPD Techniques for Land Operations, v3 (2021)

ABS, Guide for Classification and Certification of Managed Pressure Drilling Systems (2018)

IADC, UBO/MPD Operations – HSE Planning Guidelines

BSEE Technical reports on MPD case studies and early kick/loss detection

Vendor resources: SLB, NOV, Weatherford, BeyondMPD literature

He, Rui & Li, Xinhong & Wang, Yanchun & Jiang, Shengyu & Chenxiao, Zhi. (2018). A quantitative risk analysis model considering uncertain information. Process Safety and Environmental Protection. 118. 10.1016/j.psep.2018.06.029.