Well Plug & Abandonment (P&A) Guide Add Your Comments

Table of Contents

Introduction

Objectives & Constraints

Regulatory & Integrity Requirements

Planning & Pre-Work Studies

Technical Methods & Technologies

Rig vs Rigless vs Riser vs Riserless Approaches

Tubular Removal & Severing Techniques

Plug & Barrier Design (Cement, Mechanical)

Surface & Subsurface Restoration

Cost-Effective Strategies & Optimization

Trip Reduction & Integrated Operations

Automation, Digitalization, & Data-Driven Decision Making

Remote Operations & Task Certainty

Surface Footprint Minimization

Risk Management & Scope Optimization

Training, Knowledge Transfer & Collaboration

Case Studies & Examples

References & Suggested Further Reading

1. Introduction

Well P&A marks the end of a well’s lifecycle, whether it be a wildcat (exploratory) well that did not find commercial quantities, or a development/production well that has become uneconomic or reached its technical or economic limit. Proper P&A is essential for:

Preventing unwanted fluid migration (hydrocarbons, brine, gas)

Protecting groundwater and the marine environment

Complying with regulatory and societal expectations

Reducing long-term liabilities (including orphaned‐well risks)

This manual treats P&A as more than a regulatory or “close-out” activity: it is a technically challenging, multifaceted operation that must be optimized in cost, safety, environmental performance, and technical certainty.

2. Objectives & Constraints

Key objectives in P&A are:

Establish permanent barriers between all formations with potential flow (e.g., reservoirs, intermediate zones) and the surface.

Prevent migration of fluids (gas, liquids) in casing annuli or along the wellbore.

Remove or cut off above-surface/surface equipment and casing to the required depth or grades.

Restore the site (onshore) or seabed (offshore) as per environmental/regulatory requirements.

Constraints that affect P&A:

Regulatory requirements (varies by jurisdiction)

Geological/well integrity uncertainties (casing/cement condition, formation pressures)

Well depth, deviation, casing complexity, number of strings, and previous treatments

Remote location, seabed environment, water depth (for offshore)

Costs: rig costs, personnel, equipment, time

Environmental impact (emissions, surface disturbance)

3. Regulatory & Well Integrity Requirements

Many jurisdictions demand a minimum of two independent barriers between the reservoir and the surface for permanent abandonment.

Requirements may include permanent integrity of cement and casing, monitoring of annular pressures, and verification of barrier performance.

Risk-based abandonment practices (instead of purely prescriptive rules) are emerging; for example, DNV GL’s RP‐E103 for offshore wells.

Environmental regulations often require site restoration, cutting off casing below ground/seabed level, sealing, or removal of topside/subsea wellheads.

4. Planning & Pre-Work Studies

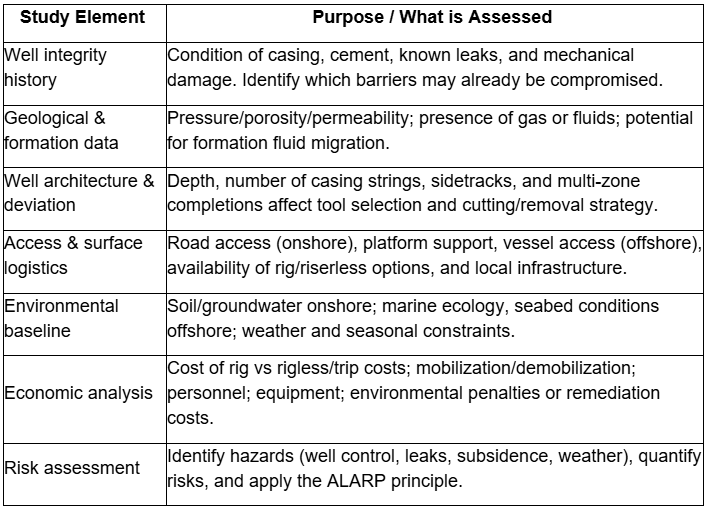

Before mobilizing heavy equipment, detailed planning is essential. Key study elements include:

Pre-planning helps reduce surprises, minimize trips, and schedule interventions that maximize operational overlap (e.g., staging of tools, combined tasks).

5. Technical Methods & Technologies

5.1 Rig vs Rigless; Riser vs Riserless Approaches

Rig-based operations: Traditional approach involving full drilling or workover rigs. Suitable for complex wells requiring heavy-duty casing severing, milling, fishing, or deep plug setting. Offers full circulation and pressure control but involves higher cost, longer duration, and greater environmental footprint.

Rigless operations: Conducted without a full rig, using lighter intervention spreads such as wireline, electric line, coiled tubing, hydraulic work units, or crane-assisted systems. Suitable for wells where barriers are already in place or when performing upper-well or surface plug work. Widely adopted in mature basins (e.g., North Sea) for significant cost and time savings while maintaining safety and regulatory compliance.

Riser-based vs. Riserless (offshore context):

Riser-based: Involves a marine or workover riser system that connects the subsea well to the surface, enabling circulation, heavy fluid control, and cement placement under full well control.

Riserless: Conducted from a vessel without a riser, using slender intervention lines (e.g., wireline, coiled tubing through lubricator or subsea intervention systems). Typically applied to shallower or already-secured wells for verification, top-hole abandonment, or conductor removal. Offers lower cost and faster execution, but limited control over well fluids and cement placement.

Where technically and regulatorily feasible, the industry trend is toward rigless and riserless interventions to reduce cost and emissions, but only after confirming well integrity and ensuring all permanent barriers are installed and verified.

5.2 Tubular Removal & Severing Techniques

Free-point / back-off / stretch analysis: To identify depths where casing or tubing is stuck vs free. Allows cutting at the optimal location, reducing pulling operations.

Cutting methods: Chemical cutters; explosives (where permitted); mechanical/hydraulic cutters; section milling (e.g., Medusa™ VS cutting technology), especially for casing severing in a single run.

Pipe & casing pulling or jacking: Remove as much tubular as economically / technically feasible; sometimes leave portions in place if removal cost outweighs benefit, as long as barriers can be established above.

Fishing/stuck tubulars: Use fishing tools, jarring, overshots, jars, etc. Planning to avoid “open hole” exposure or loss of barrier.

5.3 Plug & Barrier Design

Mechanical barriers: Bridge plugs, packers, inflatable barriers; communicate with cement plugs. Should be retrievable or verifiable.

Cement plugs: Designed to account for shrinkage, formation of channels, and gas migration. Use cement quality control, appropriate cement slurries, and additives to reduce shrinkage or extend set time.

Barriers are placed at key locations: base of the reservoir, top of the reservoir, any formation with flow potential, across permeable layers, across the casing shoe, as required by regulation.

Verification & testing: Pressure testing; integrity logs; cement evaluation tools; annulus pressure monitoring.

5.4 Surface & Subsurface Restoration

Casing cut-off below grade/seabed: Surface casing often required to be removed or cut off a few feet below ground or seabed, then capped/plugged.

Wellhead removal (onshore) or subsea wellhead removal (offshore).

Restoration of soil/seabed: Removing contamination; restoring topography; re-vegetation (onshore); seabed leveling and habitat re-establishment (offshore).

Monitoring post-P&A: surveys, emissions monitoring (e.g., methane), groundwater monitoring, periodic inspection.

6. Cost-Effective Strategies & Optimization

6.1 Trip Reduction & Integrated Operations

Reduce the number of tool trips by combining operations: e.g., perform all severing/cutting and plug setting in as few runs as possible. Tools that can do multiple jobs (cut, clear, set plug) are advantageous.

Use of high-reach or multi-purpose intervention tools (wireline/coiled tubing plus milling tool, etc.).

Preconditioning the well (clean-out, junk removal, stabilizing the wellbore) so the main P&A job runs smoothly.

Integration of services: engineering, supply chain, operations working together from an early stage; leveraging shared mobilization and demobilization, sharing personnel and equipment between wells (if geographic proximity).

6.2 Automation, Digitalization & Data-Driven Decision Making

Well integrity modeling & simulation: Before and during P&A, simulate casing/cement degradation, formation pressure, fluid migration, barrier behaviour. Allows optimization of plug designs and detection of weak zones.

Digital twin of well: Build models that reflect all known data (drilling, production, repair history) so that each decision can be optimized for that specific well.

Use real-time sensors during operations: pressures, flows, temperature; monitoring of cement placement; downhole imaging.

Use automation or remote control for tasks that are repetitive or hazardous: remotely operated vehicles (ROVs) for deepwater; remote-actuated severing tools; remote monitoring of plug setting.

6.3 Remote Operations & Task Certainty

Use remote surveillance and remote operations to reduce offshore personnel, especially on small platforms —for example, small intervention units using cranes or lightweight modular rigs.

Use of risk-based abandonment recommended practices (e.g., DNV RP-E103) to drive effort where necessary and avoid over-engineering for wells with inherently lower risk.

Use of workflow checklists, job hazard analyses, monitoring, and verification to increase certainty that the planned scope will deliver the required barrier performance.

6.4 Surface Footprint Minimization

Onshore: avoid large rig pads; use modular, mobile intervention units; limit access roads, staging areas; reuse existing infrastructure if possible.

Offshore: use riserless or limited riser spread where feasible; minimize vessel size or platform interventions; schedule operations to reduce vessel mobilization.

7. Risk Management & Scope Optimization

Perform a quantitative risk assessment early: consider threats such as fluid migration, sustained casing pressure, blowouts, environmental spills, corrosion, and structural failure.

Determine the minimal required scope of work consistent with regulatory, environmental, and long-term integrity goals. For example: pull only the casing strings needed; leave sections in place if they do not compromise barrier integrity; avoid “gold plating.”

Identify worst-case scenarios and plan contingency tools and procedures: For example, stuck pipe, casing collapse, loss of fluid control, cement failure.

Plan for monitoring, verification, and possible re-entry: document what remains in the well; what plugs/barriers are installed; produce records and as-built schematics.

8. Training, Knowledge Transfer & Collaboration

University & industry collaboration to include P&A in curriculum (well integrity, no longer focusing only on drilling/production).

Shared knowledge: case studies, best practice guidelines (e.g., IBP Guidelines, DNV, Oil & Gas UK).

Cross-disciplinary teams: geology, reservoir, drilling/intervention, environment, health & safety, regulatory.

Workshops, simulations, and field exercises to practice plug setting, cement evaluation, and emergency response for leaks.

9. Case Studies & Examples

Here are some real-world illustrations:

North Sea multi-well campaign: An agile partnership (Coretrax & service companies) saved ~32 hours of rig-time in one well in the Southern North Sea by optimizing barrier placement, using integrated tools.

Halliburton Norwegian platform campaign: Reduced headcount by ~30 %, cost lowered by ~50 % compared to traditional P&A for platform wells via an integrated well intervention strategy.

Gulf of Mexico rigless P&A: Use of cutting and milling technology (Medusa VS) in combination with mud motors allowed a Gulf well to be permanently abandoned without mobilizing a rig, yielding savings of approximately. USD 6-7 million.

10. References & Further Reading

Introduction to Permanent Plug and Abandonment of Wells (Open Access book) – covers current practices, challenges, examples from the North Sea.

DNV GL Recommended Practice RP-E103: Risk-Based Abandonment of Offshore Wells.

IBP Guidelines for Well Abandonment, 2nd Ed., 2022 (Brazilian Institute of Oil & Gas) – aligning with NORSOK D-010 and international practices.

Halliburton, Baker Hughes, Welltec, etc., technical papers on rigless and integrated P&A solutions.

Energy Workforce & Technology Council: Recommended Best Practices for Orphan Well Plugging.

Energy Workforce & Technology Council

Summary & Key Takeaways

Well P&A must balance technical integrity, regulatory compliance, environmental protection, cost, and time.

Many cost bleed points: repeated trips, rig mobilization, inefficient tool deployment, lack of data leading to over-design or surprises.

Strategies that have high leverage: moving toward rigless/riserless interventions, integrating services, using advanced cutting/severing tools, better planning and simulation, and remote/automated operations.

Risk mitigation and scope optimization ensure that you do what is needed, but no more than necessary, reducing both cost and environmental footprint.