Essential Elements of Directional Drilling

Directional drilling relies on meticulous planning and specialized equipment. Key elements include:

Well Planning: Crafting a precise trajectory from the surface to the target is foundational. This involves defining the kickoff point (where deviation begins), build rate (angle increase per distance), and hold inclination (maintaining a steady angle). Planning considers geological objectives, formation characteristics, and operational constraints, often using software to optimize the path.

Drilling Motors: Positive Drilling Motors (PDM) convert hydraulic energy from drilling fluid into mechanical power to rotate the bit, providing the torque and rotational speed needed to steer the bit. They enable sliding mode drilling, where the drill string remains stationary, and the motor directs the bit, which is critical for kickoffs, sidetracking, and multilateral wells.

PDMs feature a rotor-stator configuration (e.g., 5:6 or 7:8 lobes) that converts mud flow into rotation. Depending on size, lobe combination, material, temperature rating, and application, several PDMs are used in oil and gas drilling, including standard motors (balanced torque and speed), high-torque motors, high-speed motors, extra-power motors, and high-flow motors.

Measurement-while-drilling (MWD) Tools: provide real-time data on the well’s position (inclination and azimuth) and formation properties (e.g., gamma ray readings), allowing operators to adjust the trajectory dynamically. MWD ensures the well stays on course, enhancing precision and safety. MWD tools and motors are often modular and customizable. They cater to diverse drilling challenges, from sidetracking around fish to navigating high-angle extended-reach drilling (ERD) wells, ensuring flexibility and precision in oil and gas operations.

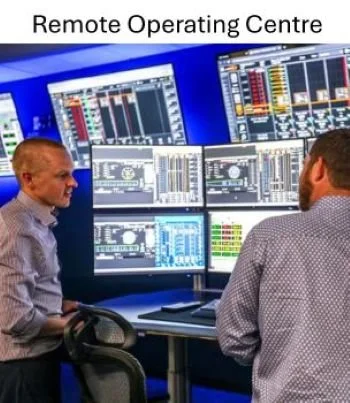

Real-Time Operation Centers: Real-time Operation Centers (RTOCs) or Remote Operations Centers (ROCs) collect and process data from Measurement While Drilling (MWD) tools, Logging While Drilling (LWD) systems, and surface sensors. This includes well trajectory (inclination and azimuth), formation properties (gamma ray and resistivity), and drilling parameters (weight on bit, torque, and pressure). ROCs identify trends, anomalies, or inefficiencies by analyzing this data in real time, enabling proactive adjustments to optimize drilling performance. Continuous monitoring detects early warning signs of problems, such as motor stalling, differential sticking, or formation instability. By addressing these issues promptly, Non-Productive Time (NPT) can be reduced significantly.