Objectives of Well Testing in Oil and Gas Wells

Well testing is a fundamental practice in the oil and gas industry that involves intentionally allowing reservoir fluids to flow to the surface under controlled conditions while measuring key parameters such as pressure, flow rate, temperature, and fluid composition. The primary purpose of well testing is to evaluate reservoir behavior and assess well performance under dynamic conditions.

Well testing is conducted at various stages of a well’s life cycle, including exploration, appraisal, development, and production. The data obtained from well tests supports critical technical and commercial decisions related to well productivity, reservoir management, completion design, and field development planning. When properly designed and interpreted, well tests help improve operational efficiency, ensure safe operations, and enhance the economic viability of hydrocarbon projects.

By analyzing pressure and flow data, engineers can estimate reservoir properties and validate subsurface models. These insights contribute to optimized resource recovery and long-term management of reservoir performance.

Understanding the Well Testing Process

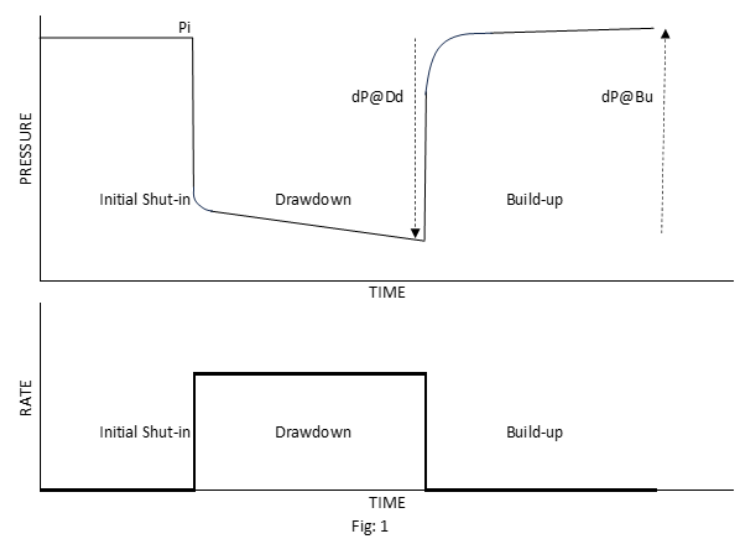

Well testing follows a structured sequence designed to capture the reservoir’s pressure and flow response over time. A typical well test consists of three main phases.

The test usually begins with an initial shut-in period, during which the well is closed to establish a stable baseline or static reservoir pressure. This phase is essential for understanding the reservoir’s initial energy and pressure conditions.

The shut-in period is followed by a drawdown phase, in which the well is opened, and fluids are allowed to flow at a controlled rate. During drawdown, the flowing pressure declines as reservoir fluids move toward the wellbore. The pressure response observed during this phase provides information about reservoir permeability, well productivity, and near-wellbore conditions.

After the drawdown period, the well is shut in again for a pressure build-up phase. During build-up, pressure recovery is monitored as fluid flow stops and the reservoir attempts to return toward equilibrium. The build-up response helps separate true reservoir characteristics from near-wellbore effects such as formation damage, partial penetration, or completion restrictions.

The combination of drawdown and build-up data allows engineers to distinguish between reservoir-controlled behavior and wellbore-related influences, leading to a more reliable interpretation of results. The figure below shows a simplistic profile of the three phases of well testing.

2. Key Objectives of Well Testing

Well testing serves multiple purposes, each contributing to a comprehensive understanding of the reservoir and well system. The following sections outline the primary objectives, drawing from established industry practices.

2.1 Assessing Reservoir Productivity

One of the primary objectives of well testing is to evaluate how effectively a reservoir can deliver hydrocarbons to the wellbore under controlled flow conditions. This assessment is based on measured flow rates, pressure behavior, and pressure transients recorded during drawdown and build-up periods. From these data, engineers estimate key parameters such as permeability, which reflects the reservoir rock’s ability to transmit fluids, and skin factor, which indicates whether near-wellbore conditions are restricting or enhancing flow.

Wells with similar initial reservoir pressures may show significantly different production performance due to variations in permeability, completion quality, or formation damage caused during drilling and completion operations. Well testing helps quantify these effects and determine whether the well can produce at commercially viable rates. The analysis also allows engineers to estimate the potential benefit of remedial actions such as acidizing, hydraulic fracturing, or recompletion. By calculating flow capacity and productivity index, engineers can forecast expected well performance and support decisions related to long-term production viability.

2.2 Identifying Fluid Types and Properties

Well testing plays a critical role in confirming the type and properties of reservoir fluids. It helps distinguish whether the well is producing oil, gas, condensate, water, or a combination of these fluids. Measurements such as gas-oil ratio (GOR), condensate-gas ratio, and water cut provide a clear understanding of the reservoir’s fluid system.

During initial flow periods, produced fluids may be contaminated by drilling mud filtrate or completion fluids. Controlled testing and proper clean-up flow help ensure that representative reservoir fluid samples are collected. Laboratory analysis of these samples provides essential information on fluid properties such as density, viscosity, composition, and the presence of contaminants such as CO₂, H₂S, or solids. These properties directly influence production strategy, surface facility design, flow assurance planning, and reserve estimation.

2.3 Determining Reservoir Pressure and Connectivity

Another key objective of well testing is to determine reservoir pressure and understand how the reservoir is connected both laterally and vertically. Pressure data obtained during shut-in periods provide estimates of initial or current reservoir pressure, while repeated tests over time help track pressure depletion.

Pressure-transient analysis can also reveal reservoir boundaries such as sealing faults, pinch-outs, or contact with aquifers. These boundary effects help estimate drainage area and effective reservoir size. In fields with multiple wells, interference or pulse tests may be conducted to evaluate pressure communication between wells. Observing pressure response in offset wells confirms hydraulic connectivity and provides valuable input for reservoir modeling, infill well planning, and enhanced recovery strategies.

2.4 Evaluating Well Integrity and Completion Quality

Well testing is an important tool for assessing well integrity and completion effectiveness. Abnormal pressure behavior or unexpected flow restrictions may indicate issues such as poor perforation efficiency, partial completion, scale buildup, or formation damage near the wellbore. Identifying these issues early allows corrective actions to be planned before full-scale production begins.

Well tests also help verify the mechanical integrity of the well by confirming pressure containment across the completion and surface equipment. Operational safety aspects, including pressure control, sand production risk, hydrate formation, and well stability under flowing conditions, are evaluated during the test. This ensures that the well can be produced safely and reliably over its intended life.

2.5 Planning Production Strategies and Field Development

Data obtained from well testing directly support production planning and field development decisions. Test results are used to select appropriate choke sizes, define initial and maximum production rates, and evaluate the need for artificial lift systems. They also provide critical input for designing surface facilities such as separators, compressors, heaters, and water-handling systems.

Well testing helps determine whether stimulation treatments are required to improve productivity and assess their effectiveness when applied. On a broader scale, test data contribute to field development planning by supporting decisions on well spacing, gathering systems, processing capacity, and phased development strategies. These inputs are essential for reliable economic evaluations and project sanction decisions.

2.6 Deciding on Well Viability and Future Actions

Ultimately, well testing provides the technical basis for deciding the well's future. Based on test results, operators can determine whether to proceed with production, perform additional completion or stimulation work, recomplete the well in another interval, or abandon it if it does not meet commercial thresholds.

In exploration and appraisal wells, well testing confirms the presence of movable hydrocarbons and their producibility, reducing subsurface uncertainty. In development and mature fields, testing helps monitor changes in reservoir performance, support reserves re-evaluation, and identify opportunities for enhanced recovery. By providing reliable, measured data, well testing helps avoid unnecessary expenditures and supports sound, value-driven decision-making throughout the life of the field.

3. Data Acquisition and Interpretation

During well testing, accurate data acquisition is critical to obtaining reliable and meaningful results. Pressures, temperatures, and flow rates are recorded continuously throughout flow and shut-in periods. Measurements are taken using a mix of surface instruments and downhole gauges, with downhole pressure gauges providing the most accurate representation of actual reservoir pressure by minimizing wellbore and surface effects. Real-time data monitoring enables test engineers to adjust flow periods, rates, and shut-in times to ensure sufficient, high-quality data is captured.

Once data are acquired, interpretation focuses on distinguishing wellbore effects from actual reservoir behavior. Early-time data are often influenced by wellbore storage and completion characteristics, while mid- and late-time data reflect radial flow and reservoir boundaries. Pressure-transient analysis techniques, including pressure-derivative analysis, are used to identify flow regimes, detect near-wellbore damage or stimulation effects, and recognize reservoir limits such as faults or sealing boundaries.

The interpreted results are then used to develop representative reservoir and well models. These models provide key inputs for reservoir simulation studies, production forecasting, and reserves estimation. By relying on measured pressure and flow responses rather than assumptions alone, well testing ensures that development and production decisions are based on a sound, data-driven understanding of the reservoir and the well’s performance.

References and Further Reading

Aghar, H. 2005. "The Expanding Scope of Well Testing." Oilfield Review, Schlumberger. https://www.slb.com/-/media/files/oilfield-review/p44-59-english.

Blasingame, T. A. 2015. "Testing Exploration Wells by Objectives." SPE-013184-MS, Society of Petroleum Engineers. https://blasingame.engr.tamu.edu/z_zCourse_Archive/P648_15A/P648_15A_Lectures_%28working_lectures%29/20150204_P648_15A_Lec_03_SPE_013184_%5BPDF%5D.pdf.

Gringarten, A. C. 2021. "Well Test Analysis in Practice." Journal of Petroleum Technology, Society of Petroleum Engineers. https://jpt.spe.org/twa/well-test-analysis-practice.

Lee, J. 2007. "Pressure Transient Testing." Textbook, Society of Petroleum Engineers.

Matthews, C. S., and Russell, D. G. 1967. "Pressure Buildup and Flow Tests in Wells." Monograph, Society of Petroleum Engineers.

Schlumberger. 2024. "The Defining Series: Well Testing Fundamentals." Schlumberger. https://www.slb.com/resource-library/oilfield-review/defining-series/defining-well-testing.

Society of Petroleum Engineers. 2023. "Well Test Interpretation." Training Course, Society of Petroleum Engineers. https://www.spe.org/en/training/courses/well-test-interpretation/.